Physics-Based Yield Forecasting: Addressing the Modelling Gap for Next-Gen PV

Next-gen module technologies demand a new approach to yield forecasting. This article explores where legacy tools fall short on spectral and electrical modelling, and how physics-based simulation helps manufacturers build a credible path from lab innovation to bankable field performance.

· Ben Sudbury · 4 min read

Module manufacturers are pushing past the 30% efficiency barrier in the lab, but standard yield models (built for the single-junction era) can’t accurately forecast how these innovations will perform in the field. Without credible energy yield predictions, it is difficult to demonstrate the value of next-gen technology to developers, financiers, and independent engineers. A physics-based simulation approach is needed to bridge the gap from lab records to bankable field performance.

Recent developments in perovskite-silicon tandems and advanced thin-film technologies are pushing the boundaries of what is possible in the lab. However, for manufacturers bringing these innovations to market, a lab efficiency record alone is not enough. Developers and independent engineers need to see accurate field performance forecasts before they will adopt a new module technology, and current modelling software struggles to provide them.

Standard yield tools rely on simplified factors to account for spectral shifts and electrical mismatch. While sufficient for standard silicon modules, these approximations break down when applied to next-generation technologies that are inherently sensitive to the solar spectrum or rely on complex electrical architectures to mitigate shading. The result is that the very innovations a manufacturer has invested in are undervalued, or worse, penalised by the tools the market uses to make purchasing decisions.

The Spectral Challenge: Tandems and Thin-Films

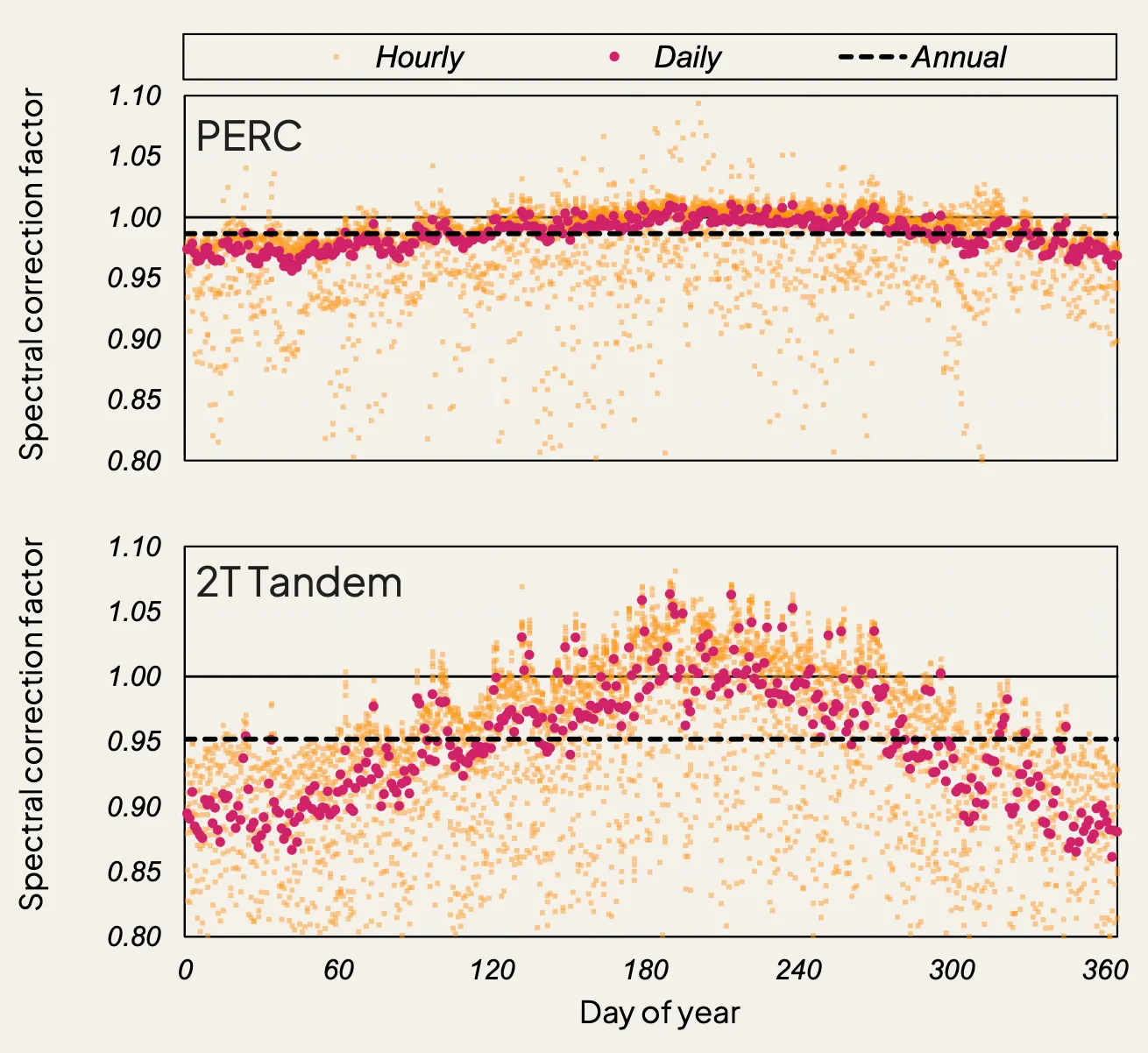

For two-terminal (2T) tandem devices, spectral variation is not a minor correction factor; it is a fundamental driver of performance.

Because the top and bottom cells must be current-matched, the device output is limited by the sub-cell generating the least current. In the field, the solar spectrum shifts constantly throughout the day and from season to season. Standard modelling tools, which often assume a fixed spectral shape or apply simple precipitable water vapour (PWV) corrections, cannot capture the dynamic current mismatch between sub-cells caused by these shifts.

Research presented at the IEEE PVSC highlights that spectral effects are significantly stronger for perovskite-silicon tandems than for PERC cells, leading to potential yield forecast errors if not modelled correctly.

SunSolve addresses this by performing a full spectral solve at every time step. By integrating the specific quantum efficiency (EQE) of each sub-cell with a ray-traced environmental spectrum, it calculates the precise current generation of each layer dynamically. This capability extends to other spectrally sensitive technologies, such as CdTe (where spectral shift is a key performance differentiator) and emerging down-converter materials designed to manipulate incident light.

M.D. Abbott et al., “Spectral correction in yield forecasts for two-terminal perovskite–silicon tandem modules.” IEEE 53rd PVSC 2025.

The Electrical Challenge: Shade-Tolerant Architectures

Beyond spectral physics, the industry continues to explore designs that actively mitigate mismatch losses such as Tesla’s new 18 zone shade resistant module or “hot-spot free” designs.

Validating the benefit of these designs requires more than a geometric shading factor, it requires solving the full electrical circuit. Standard tools typically apply a linear “electrical shading factor” that estimates the impact of beam shading on the string. This approach often fails to capture the non-linear behaviour of bypass diodes and reverse-bias breakdown in complex wiring schemes.

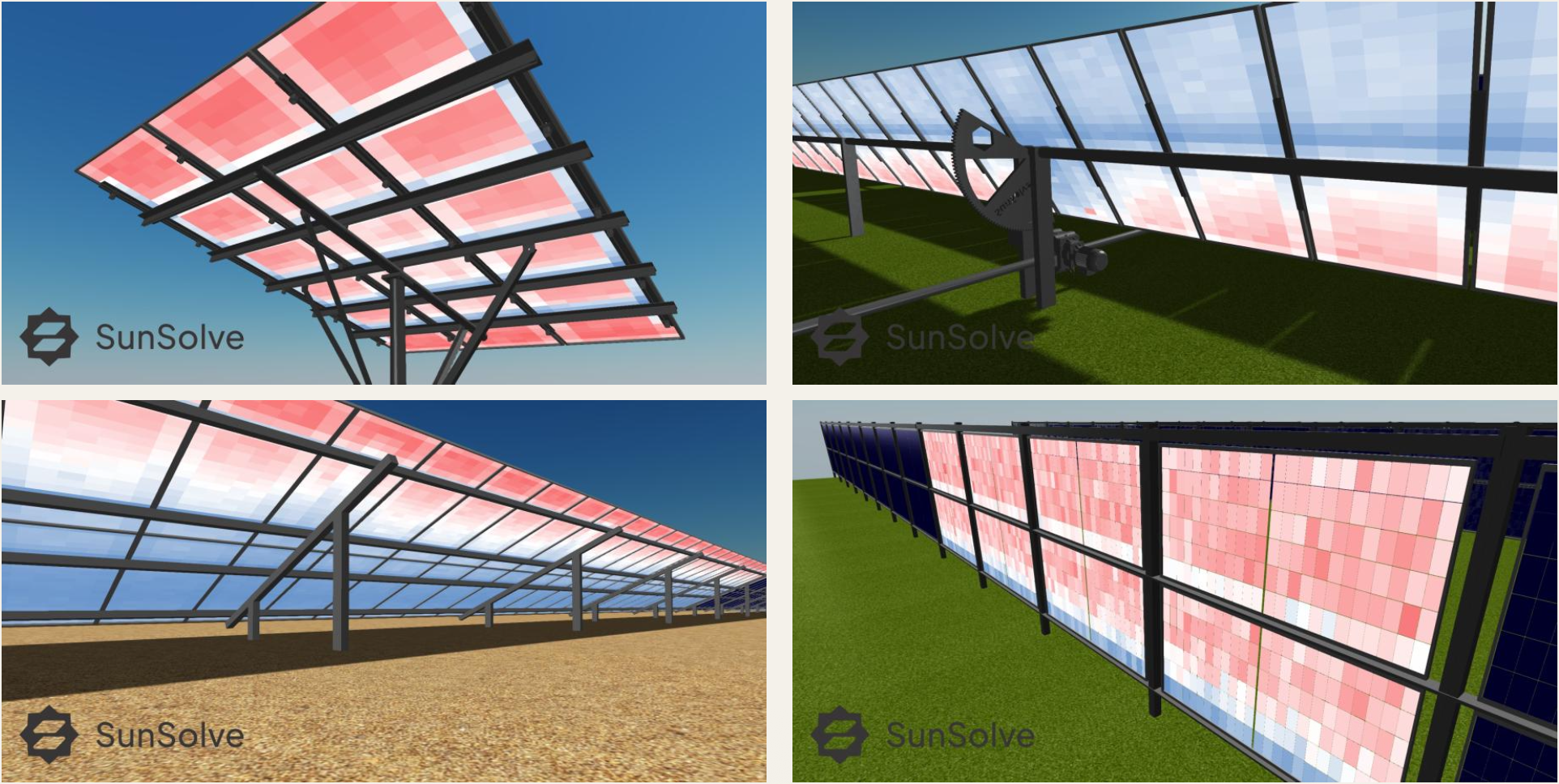

SunSolve utilises a coupled opto-electrical engine that solves the equivalent circuit from the sub-cell level up to the full string. This allows engineering teams to quantify exactly how a specific shade-tolerant design recovers energy during partial shading events (e.g. from tracker torque tubes, localised soiling or inter-row shading) compared to a standard layout.

Bridging the Gap to Bankability

While physics-based simulation provides the necessary accuracy for internal product validation, the downstream market relies on standardised reporting for project finance.

SunSolve is designed to bridge this gap. While SunSolve Yield can calculate annual yield, it is also designed to work with industry standard solutions like PVsyst. SunSolve can automatically calculate physics-based spectral mismatch modifiers, shading and transparency factors along with electrical mismatch factors.

This workflow allows manufacturers to provide independent engineers and customers with validated, defensible inputs for their own financial models, replacing conservative default assumptions with data derived from the device’s actual physics.

A Unified “Digital Twin” for R&D and Deployment

Adopting a physics-based workflow offers a strategic advantage: it unifies the disparate goals of R&D and product teams.

Instead of maintaining separate models for cell efficiency (R&D team) and energy yield (product team), manufacturers can utilise a single digital twin. The R&D team can use this model to prototype cell variations (such as optimising the perovskite bandgap or layer thickness) specifically for maximum energy yield in target markets, rather than just STC efficiency. This same validated model is then deployed to forecast field performance, ensuring that product development is driven by the metric that matters most to the end customer: energy yield.

Watch the full presentation to see how we model these advanced physics:

Dr Malcolm Abbott walks through SunSolve’s vertically integrated simulation pipeline, from wafer-level optics and cell-level equivalent circuits through to module digital twins and full system energy yield.